Production

For shaft-like parts, turning and milling centres, some equipped with automated part feeding systems, are used. The subsequent milling work, which establishes the specific reference to the teeth, involves complex clamping work. Here, we machine the gear parts with one or two-spindle machining centres.

The teeth are produced on many parts through interior broaching. For this, an electro-mechanical broaching machine is used, which can process up to 3 parts simultaneously. In our facilities we are also capable of setting up the necessary grinding processes for generating special surface finishes.

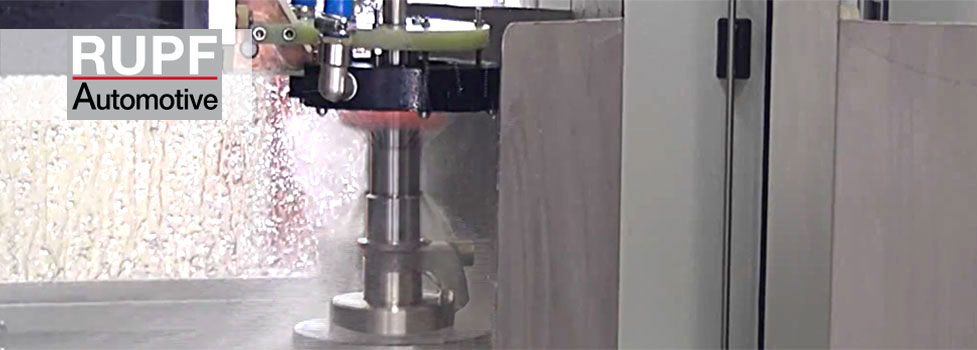

Inductive hardening with the associated quality checks accompanying production is done in-house. For special work operations such as mandrel hardening, case hardening or nitrocarburising as well as surface treatments designed specifically for the case at hand, we make use of external subcontractors.